STEEL KEN has specialized in the manufacturing of metal mechanical components for nearly 40 years, gaining extensive experience across a wide range of applications with a reputation for stable and reliable quality. We are capable of processing various materials, including steel, aluminum alloys, copper, stainless steel, and engineering plastics, serving diverse industries such as motorcycles, automobiles, bicycles, electronics, and precision machinery.

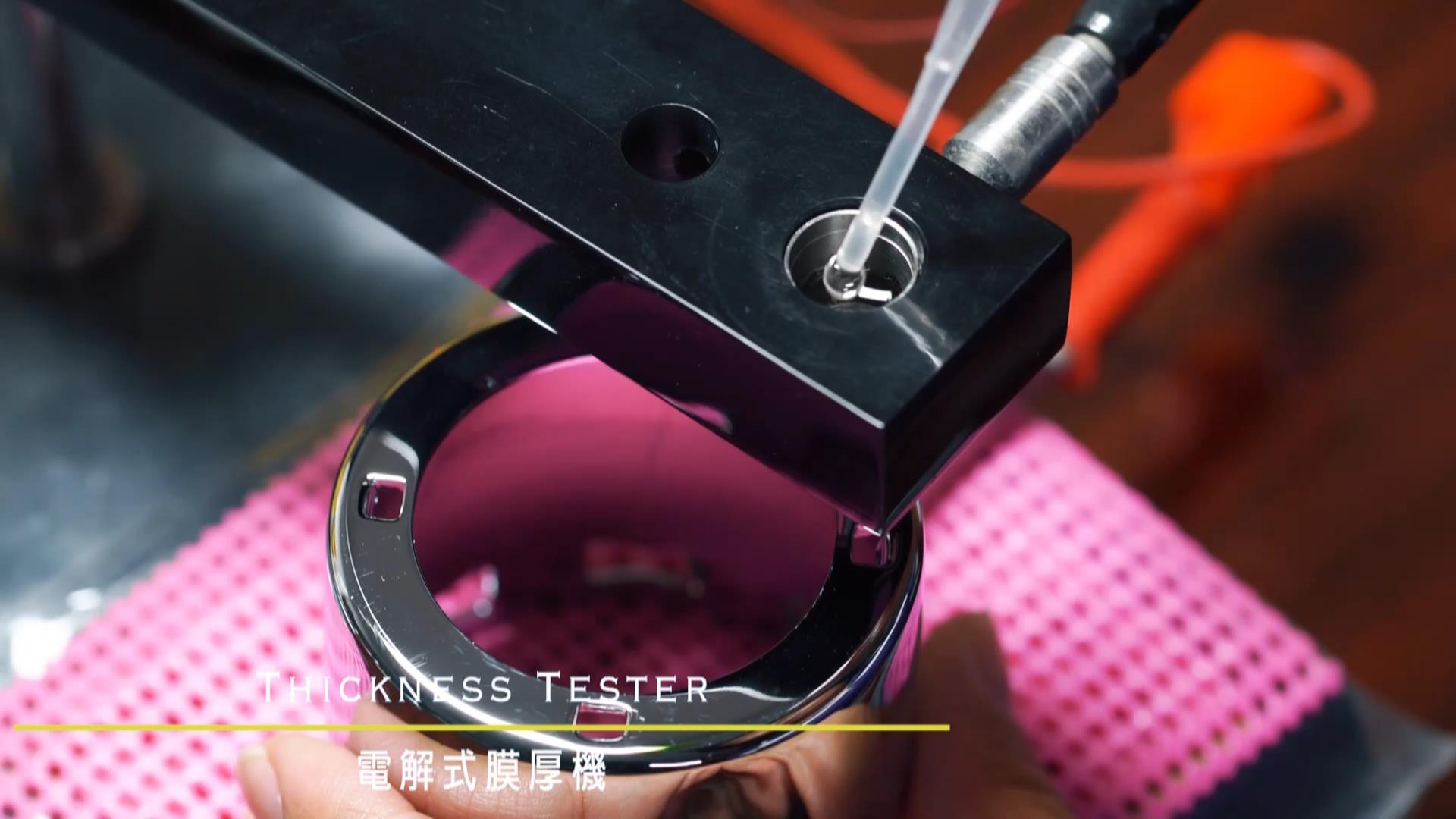

Based on customer requirements or product drawings, we provide comprehensive secondary processes, including anodizing, heat treatment, ID/OD grinding, plating, and powder coating. Finished components, whether painted, plated, electrophoretic coated, or powder coated, are tested to withstand acid and alkali exposure, salt spray, and UV resistance, ensuring durability and consistent quality.